驱动器

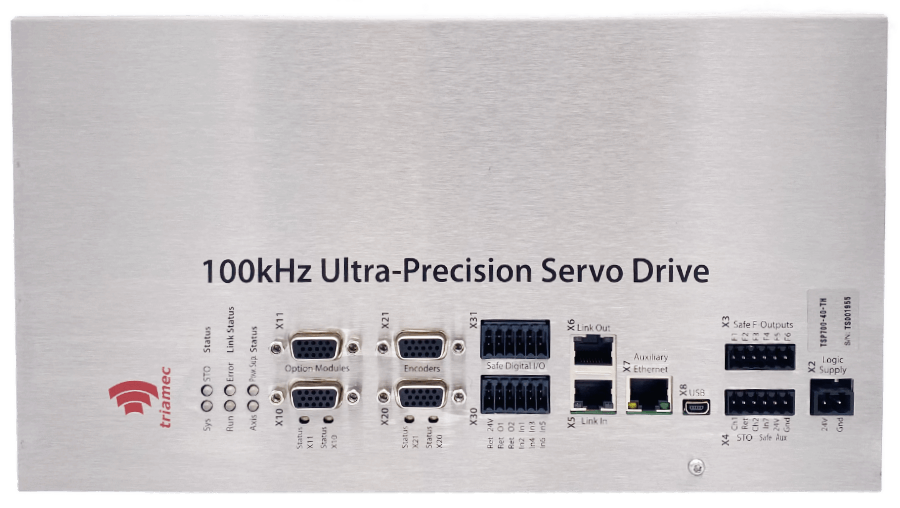

100kHz控制,最高800V,40Arms/80A峰值

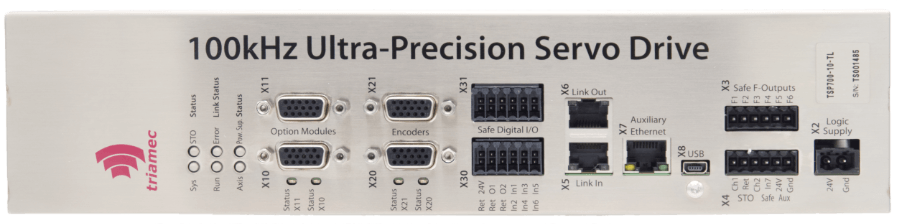

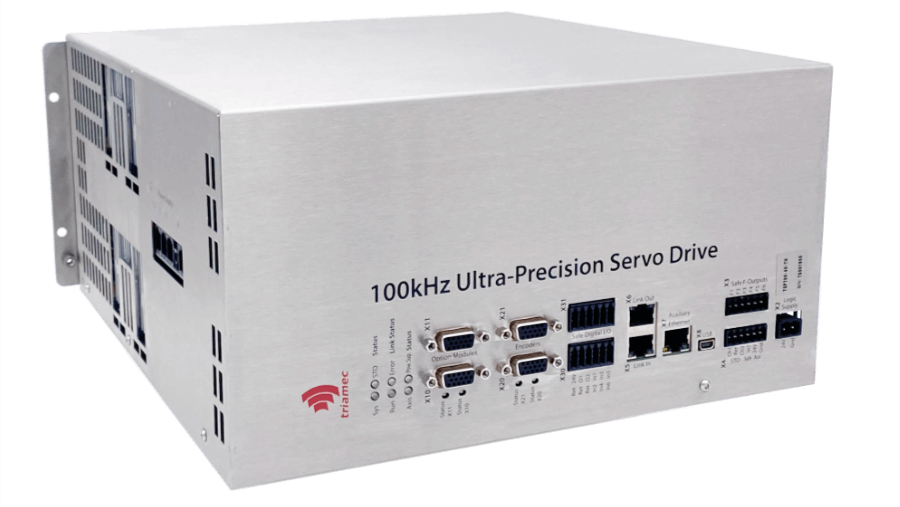

Triamec 伺服驱动器具有卓越控制特性(静止抖动<0.1nm),满足 平行运动系统、超精密加工、定位主轴和定位工作台等应用要求。 TSD 系列将两个完整的伺服驱动器组合在一个外壳中,电流和位置控制器以 100kHz同步工作。TSP 系列集成交流电源,通过 3 级 100kHz PWM 技术显着降低功耗,降低主轴电机的热损耗,提高整体精度。

基于以太网的现场总线Tria-Link或 EtherCAT实现与主机 PC 的通讯连接, 另外,Triamec 伺服驱动器也可以独立运行,无需现场总线。

通过独立于现场总线的辅助以太网和 USB 连接执行调试、检查和优化。 Windows 软件TAM System Explorer可以方便地访问所有驱动器及其寄存器,以高达 100kHz 的采样率实时显示和记录。

可使用Tama 在驱动器内进行编程,实现顺序控制、高级控制或者轴间耦合控制等。

PC作为控制器在 Windows下使用TAM API或Beckhoff TwinCAT,可用C#实现。

硬件和软件选项可用于双回路控制、2MHz/18 位模拟编码器、模拟 I/O、FFT、激光 PWM 和其他应用,请参见下表。

特点

- 100kHz电流和位置环控制

- 10kHz路径规划 / 轴耦合

- 带有 5 个滤波器块的 PID 控制,SI 单位

- 具有 65536 倍插值和自动校准的 sin/cos 编码器

- 10kHz 自由编程

- 冗余STO

优点

- 最高刚度

- 快速响应干扰

- 精准定位

- 主动抑制共振

- 出色的噪声抑制

TSD系列:双轴,24~365VDC直流供电,单轴功率0.5~6.9kW

| # |

PWM |

VDC |

Arms |

Apeak** |

Motor |

Dimensions |

||

| TSD80-06 |

2 |

2 Level |

80 |

24-85VDC |

6 |

6 |

460 |

51x230x170 |

| TSD80-10 |

10 |

20 |

1100 |

|||||

| TSD80-15 |

15 |

30 |

1650 |

|||||

| TSD130-10 |

130 |

24-135VDC |

10 |

20 |

1680 |

|||

| TSD350-10 |

350 |

24-365VDC |

10 |

20 |

4600 |

68x262x230 |

||

| TSD350-15 |

15 |

30 |

6900 |

* 6 for DC; 4.2 for AC

** 14s maximum for TSD80 and TSD130, 1.4s maximum for TSD350. The drive continuously calculates a thermal model (i^2*t) for the three motor phases and for the three drive phases and switches off before damage can occur.

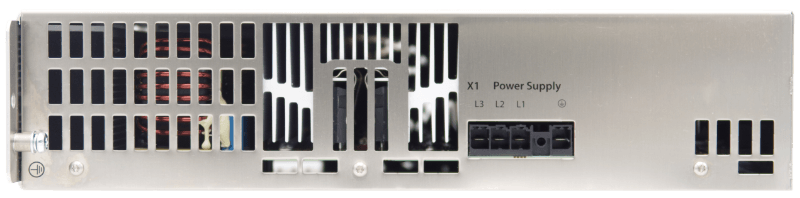

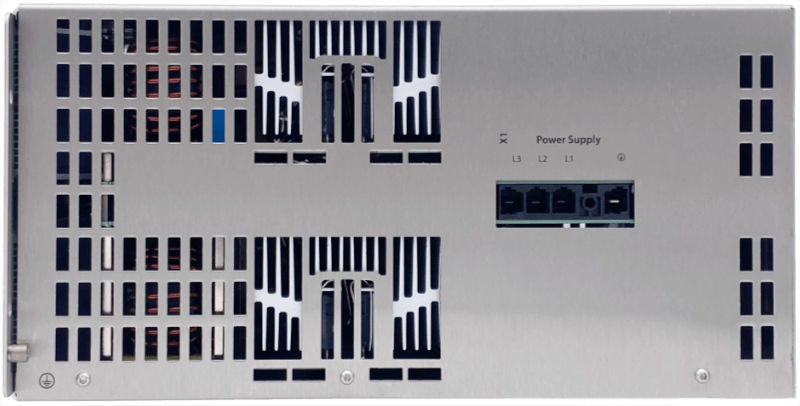

TSP系列: 单轴,38-480V AC交流或50-770V DC直流供电,9.5-38kW

| # |

PWM |

VDC |

Power |

Arms |

Apeak** |

Motor |

Dimensions |

|

| TSP700-10 |

1 |

3 Level |

700 |

38-480VAC |

10 |

20 |

9.55 |

69x315x295 |

| TSP700-20 |

20 |

40 |

19.1 |

|||||

| TSP700-40 |

40 | 80 | 38.2 | 152x315x308 |

** 1.4s maximum. The drive continuously calculates a thermal model (i^2*t) for the three motor phases and for the three drive phases and switches off before damage can occur.

Key to the new product and option nomenclature from fall 2020.

产品特点

| Supported Motors | 2 and 3 phase synchronous or asynchronous AC, DC |

| Protection | Overtemperature: Drive, motor (KTY83/84, PT100, PT1000, PTC-1K); i2t, overvoltage, overcurrent |

| Safety | Safe Torque Off: SIL3/PLe |

| Position Measurement Analog | Sin/Cos 1Vss: 65536-fold interpolation, auto calibration, 500kHz cut-off frequency (true interpolation up to 2MHz, quadrature up to 10MHz with option module) |

| Position Measurement Incremental |

RS422: max. pulse frequency 10MHz TTL: max. pulse frequency 2.5MHz |

| Position Measurement Digital |

EnDat 2.1 & 2.2, BiSS B, BiSS C, Tamagawa, Nikon (encoder types with additional sin/cos signals are recommended - specifications see 'Position Measurement Analog') |

| Sensorless | Sensorless commutation/control, suitable for fast spindles |

| Digital In Per Axis | 6 inputs opt. isolated, 24V , 2x 300μs, 4x 1200μs 4 TTL level general purpose digital inputs per axis on encoder DSub connector |

| Digital Out Per Axis | 2 outputs opt. isolated, 24V 1A |

| Option Modules | 2 sporting a D-Sub HD15 Connector, see Hardware Options below |

| Logic Supply | 24VDC ±10% @ 1.5A - 2.5A max. (incl. 2 Option Modules) |

| Field-bus - real time | EtherCAT 100Mbps / Tria-Link 200Mbps. Tria-Link allows for direct transmission of values from one servo drive to others on the same bus. |

| Service interfaces | USB / Ethernet |

| Programming on the Drive |

Freely programmable with Tama in 10kHz real-time clock in Microsoft® C#, incl. axis couplings; additional asynchronous task |

| PC Programming | TAM API for Microsoft® .NET Framework; Beckhoff TwinCAT with CNC; Python |

Subject to technical changes.

总线形式

| E | EtherCAT |

| T | Tria-Link |

换相速度

| L | Simplified Export. A drive with this option supports electrical commutation frequencies <600Hz. |

| H | High Speed. A drive with this option supports electrical commutation frequencies >=600Hz and is subject to export restrictions to some countries. |

硬件可选模块

反馈

| EN | Additional Standard 16bit Sin/Cos/RS485 Encoder, e.g. for Dual-Loop Control |

| EH | High-Speed 2MHz 18bit sin/cos Encoder, quadrature up to 10MHz |

I/O

| AN | Analog Inputs ±5/10V, 16bit |

| AO | Analog Outputs, ±10V, 16bit |

其他选项

| FF | Fast Fourier Transform Module, 1Vpp, 16bit |

| PT | Pulse Train Out, also for driving laser modules |

| NO | Placeholder: no module in this slot. |

如上硬件模块适合所有TSD和TSP系列,每个驱动器最多选择两个模块。详见手册文档。Documents.

* Upcoming

软件功能选项

| FS | Functional Safety |

| GY | 100kHz MIMO gantry control with decoupled linear position and yaw displacement loops |

| PU | Pulsing Unit for hardware generated position synchronized pulses up to 10MHz, pulse position and distance can be chosen freely (64bit float) - requires EN or EH hardware option |

| XC | Eccentricity compensation, averages 2 sensors on opposite sides of an encoder disc. |

配置示例

| Series | DCV | ‑ | Arms | ‑ | Variants | [‑ | Option Modules | [‑ | SW Options]] |

| TSD | 350 | ‑ | 10 | ‑ | EH | ‑ | ENFF | ‑ | FSPUXC |

| TSP | 700 | - | 30 | - | TL | - | ANNO | ||

| TSD | 130 | - | 10 | - | EL | - | NONO | - | GY |

| TSP | 700 | - | 10 | - | TH |

The TSD350-10-EH-ENFF-FSPUXC is a dual-axis servo drive with 350V nominal voltage, 10Arms per axis and EtherCAT fieldbus, supporting electrical commutation frequencies >=600Hz. It has an additional encoder module on extension slot 0 and a fast Fourier transform module on slot 1. The drive further includes the software options functional safety, pulsing unit (on the EN module) and eccentricity compensation.

Incorrect designations

TSD80-10-EH-NONO ❌ (Without software options, NONO is not needed.)

TSD80-10-EH-GY ❌ (GY could be mistaken as an option module.)

TSD80-10-EL-AN ❌ (When there is only one option module, the empty slot must be indicated with NO.)

TSD80-10-EH-[EH]-[ANNO]-[GY] ❌ (2 to 4 dashes are correct, 0, 1 and >4 are incorrect. No brackets.)